Enhance Workplace Safety with Comprehensive Safety Audits

For Quick response for Safety Audit in India you can mail safety@elion.co.in in or call us at 9013890526 or Whatsapp by Clicking here.

At Elion Technologies and Consulting Pvt Ltd, we take pride in providing comprehensive Safety Audit Services designed to identify hazards, evaluate risks, and ensure compliance with national and international safety standards. Our services are tailored to enhance safety, protect assets, and foster a secure environment across diverse industries. The audit serves as a critical tool for identifying potential hazards, assessing compliance with safety regulations, and implementing best practices to ensure a safe working environment for all employees. Through systematic evaluation and analysis, Elion strives to foster a culture of safety and continuous improvement.

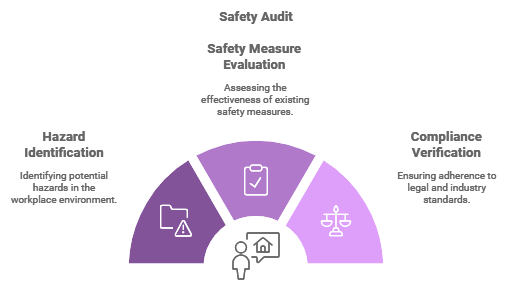

A Safety Audit is a comprehensive review of workplace practices, systems, and environments to identify hazards, evaluate the effectiveness of safety measures, and ensure compliance with legal and industry standards. Unlike routine checks, it provides a deeper assessment, uncovering hidden risks and offering actionable recommendations to improve safety and minimize liabilities.

Safety audits are essential for maintaining a safe workplace and ensuring compliance with legal and regulatory requirements. Elion’s safety audit process involves a thorough examination of existing safety measures, employee training programs, and incident reporting systems. The goal is to identify areas for improvement and develop actionable recommendations. At Elion, our audits align with various National, International and ISO Standards ensuring all hazards are identified and mitigated. Our team of experts conducts in-depth inspections, provides actionable insights, and helps clients achieve their safety goals.

Schedule Your Safety Audit Today

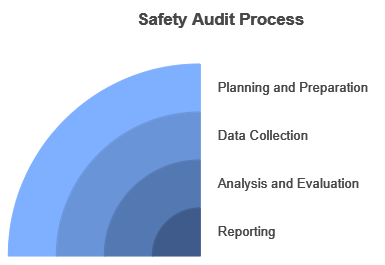

Safety Audit Process

1. Planning and Preparation: The audit begins with careful planning, which includes defining the scope, objectives, and criteria for the audit. Key stakeholders are identified, and an audit team is assembled to carry out the evaluation.

2. Data Collection: Data is collected through various methods, including:

- Interviews: Engaging with employees to gather insights on safety practices and concerns.

- Document Review: Analyzing safety policies, training records, and incident reports.

- Site Inspections: Conducting walkthroughs of the facility to observe safety conditions and practices.

3. Analysis and Evaluation: The collected data is analyzed to identify trends, gaps, and areas of non-compliance. The audit team evaluates the effectiveness of current safety measures and assesses the overall safety culture within the organization.

4. Reporting: A detailed audit report is compiled, summarizing findings, conclusions, and recommendations. This report is presented to management and relevant stakeholders for review and action.

Request a Consultation

Key Results of Safety Audit

The audit revealed several key findings, including:

Compliance Gaps: Areas where safety practices did not meet regulatory standards.

Training Needs: Identified gaps in employee training related to safety protocols.

Hazardous Conditions: Specific locations within the facility that posed safety risks.

Recommendation

Based on the findings, the following recommendations are proposed:

Enhance Training Programs: Develop and implement comprehensive safety training for all employees.

Regular Safety Inspections: Establish a schedule for routine safety inspections to identify and address hazards promptly.

Improve Reporting Systems: Create a more efficient incident reporting system to encourage employees to report safety concerns without fear of reprisal.

Case-study of Safety Audit

Get Your Custom Safety Audit Plan

Industry Served for Safety Audit

At Elion Technologies and Consulting Pvt Ltd, we serve a diverse range of industries, tailoring our expertise to meet their unique safety needs. Our services extend to manufacturing units, ensuring operational safety in factories and production facilities; pharmaceutical plants, where we address stringent safety protocols for chemical handling and cleanroom environments; and the oil and gas sector, where we specialize in fire, explosion, and environmental risk management. We also cater to educational institutions, safeguarding schools and colleges, and the hospitality industry, including hotels and restaurants, ensuring guest and employee safety. Our scope includes construction sites, focusing on worker safety and site compliance, as well as warehouses and logistics operations, where we streamline safety in material handling and storage. Additionally, we support financial institutions, healthcare facilities, and infrastructure projects, offering customized safety solutions for each. No matter the industry, Elion is committed to enhancing safety, mitigating risks, and fostering secure environments.

The safety audit conducted by Elion is a vital step toward ensuring a safe and compliant workplace. By addressing the identified gaps and implementing the recommended actions, Elion can enhance its safety culture and protect the well-being of its employees. Continuous monitoring and periodic audits will further strengthen safety practices and foster a proactive approach to workplace safety.

Enhance Workplace Safety

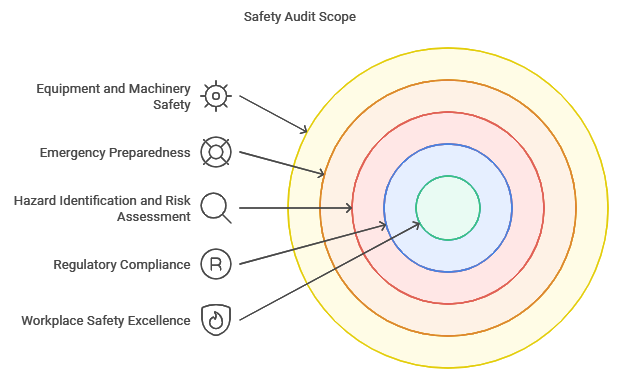

Scope of Safety Audit

The scope of a safety audit encompasses a detailed and methodical examination of all aspects of workplace safety to ensure compliance, mitigate risks, and foster a secure working environment. A well-defined safety audit scope addresses critical areas, offering actionable insights to enhance safety protocols and align with regulatory standards. Below is a comprehensive breakdown of the scope of a safety audit that sets the benchmark for workplace safety excellence:

1. Regulatory Compliance

2. Hazard Identification and Risk Assessment (HIRA)

3. Emergency Preparedness

4. Equipment and Machinery Safety

5. Fire Safety and Prevention

6. Electrical Safety

7. Chemical Safety and Hazardous Materials Management

8. Employee Training and Safety Culture

9. Personal Protective Equipment (PPE)

10. Documentation and Record Keeping

11.International and National Standards for Safety

Partner with Experts

FAQs

A comprehensive safety audit is a systematic evaluation of a workplace’s safety protocols, practices, and compliance with regulations to identify potential hazards and recommend improvements.

Safety audits help prevent accidents, injuries, and legal liabilities by proactively addressing safety concerns and ensuring compliance with industry standards.

Our safety audits are conducted by certified auditors, and moreover, they have over three decades of combined experience across various fields. This ensures a thorough assessment.

The duration varies based on the size and complexity of your workplace. However, generally, audits are completed within a few days to a week.

Yes, our auditors have experience across diverse industries, allowing them to tailor their approach to your specific workplace needs.

Safety audits lead to improved employee well being, regulatory compliance, cost savings through risk reduction, and a more secure work environment.

Yes, you will receive a comprehensive audit report outlining findings, recommendations, and step-by-step action plans.

You can schedule a safety audit by contacting us through our website or reaching out to our customer support.

We serve a wide range of industries, including manufacturing, healthcare, construction, hospitality, and more. Additionally, our expertise spans diverse sectors.

Absolutely, we prioritize the confidentiality of all audit findings and discussions.

Yes, we provide ongoing consultation to help you implement and maintain the recommended safety improvements.

Yes, we offer virtual safety audits. Furthermore, these are particularly beneficial for remote or geographically dispersed workplaces.

Safety audits, in essence, identify potential hazards and weak points. Consequently, this allows you to take corrective actions before accidents occur.

While we provide detailed recommendations, additionally, we can also offer guidance and support as you implement the changes.

Yes, our audits, moreover, ensure that your workplace adheres to industry regulations and standards.

Yes, by addressing safety concerns, furthermore, you may lower the risk of accidents and injuries. Consequently, this could potentially reduce insurance premiums.

Neglecting audit recommendations, in fact, may lead to increased risks. Additionally, it can result in potential accidents and legal liabilities.

Safety audits can be a one-time service; however, for continued safety improvement, regularly scheduled audits are recommended.

Yes, demonstrating a commitment to workplace safety, furthermore, can enhance employee morale and job satisfaction.

Getting started is easy. Additionally, simply reach out to us through our website or contact our customer support, and we’ll guide you through the process, including Electrical Safety and Wiring Inspection if needed.

A safety audit is a systematic evaluation of a workplace or a process, and consequently, it aims to identify potential hazards, assess compliance with safety regulations, and ensure the well-being of employees and the environment. The specific elements to include in a safety audit may vary based on the nature of the organization, industry, and applicable regulations. However, here are some common components that a safety audit should include:

Hazard Identification and Risk Assessment:

- Identify potential hazards and risks associated with the workplace, processes, equipment, and materials.

- Evaluate the severity and likelihood of each hazard to prioritize corrective actions.

Compliance Review:

- Review compliance with relevant local, state, and federal safety regulations, standards, and codes.

- Ensure adherence to company-specific safety policies and procedures.

Physical Environment Inspection:

- Inspect the physical layout of the workplace, including facilities, equipment, machinery, storage areas, and workspaces.

- Check for ergonomic considerations, fire safety measures, electrical safety, ventilation, and other physical factors.

Emergency Preparedness:

- Assess the availability and functionality of emergency exits, evacuation plans, fire alarms, extinguishers, first aid kits, and other emergency equipment.

- Review training and drills for employees on responding to emergencies.

Personal Protective Equipment (PPE) Assessment:

- Evaluate the use and availability of appropriate PPE for employees to ensure their safety against identified hazards.

Training and Education:

- Review the effectiveness of safety training programs for employees at all levels.

- Ensure that employees are aware of potential hazards and are equipped with the knowledge to mitigate risks.

Incident Reporting and Investigation:

- Examine incident reporting and investigation processes to ensure that accidents, near-misses, and other safety concerns are properly documented and analyzed.

- Verify that corrective actions are taken to prevent future incidents.

Documentation and Recordkeeping:

- Check the accuracy and completeness of safety-related documentation, including safety manuals, procedures, training records, and incident reports.

Safety Culture Assessment:

- Evaluate the organization’s safety culture, including management commitment, employee engagement, and communication about safety matters.

Contractor and Outsourced Services Evaluation:

- If applicable, assess the safety practices of contractors and outsourced service providers who work on-site.

Environmental Health and Safety (EHS) Programs:

- Review EHS programs that address environmental concerns and ensure the safe handling and disposal of hazardous materials.

Continuous Improvement:

- Identify opportunities for improvement and suggest corrective actions to address deficiencies and enhance safety measures.

There are several types of safety audits, each with a specific focus and purpose. Here are three common types of safety audits:

Compliance Audit: A compliance audit focuses on evaluating an organization’s adherence to relevant laws, regulations, standards, and internal policies. It ensures that the workplace is meeting the required safety and health standards set forth by governmental agencies or industry-specific bodies. The audit identifies any gaps in compliance and recommends corrective actions to bring the organization into alignment with the necessary regulations. This type of audit is crucial for avoiding legal liabilities and ensuring that the organization operates within the boundaries of the law.

Process Safety Audit: Process safety audits are specifically targeted at industries that involve the handling of hazardous chemicals, processes, and technologies. These audits assess the effectiveness of safety management systems, engineering controls, and operational procedures in preventing accidents, releases, and other catastrophic incidents. Process safety audits typically focus on elements such as risk assessments, management of change, emergency response plans, equipment integrity, and employee training related to hazardous materials and processes.

Behavioral Safety Audit: A behavioral safety audit concentrates on evaluating the safety culture and behaviors of employees within an organization. It assesses how well safety protocols and practices are integrated into daily routines and how effectively employees follow safety procedures. This type of audit often involves observing employees’ actions, interactions, and attitudes related to safety. It helps identify areas where further training, communication, or cultural changes are needed to foster a safer work environment.

It’s important to note that these are just a few examples of safety audits, and there may be other specialized types depending on the industry and specific safety concerns of an organization. Choosing the right type of audit depends on the goals, risks, and focus areas that need to be addressed to improve overall safety performance.

It seems like you’re asking for the definition or explanation of a safety audit. A safety audit is a systematic and structured evaluation process conducted to assess the effectiveness of an organization’s safety and health management systems, procedures, policies, and practices. The primary goal of a safety audit is to identify potential hazards, assess compliance with relevant regulations and standards, and ensure the well-being of employees, visitors, and the environment.

A safety audit involves a thorough examination of various aspects of an organization’s operations to determine whether they meet established safety criteria. The audit process may include inspections, documentation reviews, interviews with employees, and observations of work practices. The findings from the audit help identify strengths, weaknesses, and areas for improvement in the organization’s safety performance.

Key features of a safety audit include:

Objective Evaluation: A safety audit is conducted by impartial and knowledgeable auditors who objectively assess safety practices and systems.

Systematic Approach: The audit follows a structured and organized approach, often using checklists or guidelines, to ensure that all relevant aspects are reviewed.

Identification of Hazards: The audit aims to identify potential hazards, risks, and unsafe conditions within the workplace.

Compliance Assessment: The audit assesses compliance with local, state, federal, and industry-specific safety regulations, as well as internal policies and standards.

Documentation Review: Safety-related documentation, such as policies, procedures, training records, and incident reports, is examined for accuracy and completeness.

Employee Involvement: Employees at various levels may be interviewed or consulted to gather insights into safety practices and concerns.

Recommendations: Based on the audit findings, recommendations for corrective actions and improvements are provided to enhance safety performance.

Continuous Improvement: A safety audit is part of an ongoing process aimed at continuous improvement in safety management and practices.

Safety audits play a crucial role in preventing accidents, reducing workplace injuries and illnesses, and fostering a culture of safety within an organization. The results of safety audits can guide management in making informed decisions to allocate resources, implement changes, and prioritize safety initiatives.

You can refer to the Ministry of Labour and Employment, Government of India.

You can explore specific standards from the Bureau of Indian Standards (BIS).

The Occupational Safety and Health Association (OSHA) India provides valuable insights and resources.

Check out the Indian Safety Professionals Association (ISPA) for professional development opportunities.

The National Safety Council (NSC) India offers safety training programs.

You can connect with Indian Occupational Safety and Health Association (IOSHA) for industry-specific insights.

Refer to this page on safety regulations in India.

Explore reliable safety audit services in India.

Discover construction safety standards through Bureau of Indian Standards (BIS).

Stay updated on safety practices through Indian Safety Professionals Association (ISPA).

Learn about workplace safety from Occupational Safety and Health Association (OSHA) India.

The National Safety Council (NSC) India offers business-related safety resources.

Connect with fellow professionals through Indian Occupational Safety and Health Association (IOSHA).

Discover audit requirements for manufacturing units through Bureau of Indian Standards (BIS).

Explore audit guidelines and templates through reliable safety audit services in India.

Get healthcare safety insights from Occupational Safety and Health Association (OSHA) India.

The National Safety Council (NSC) India provides safety publications and research papers.

Stay updated on safety news and events through Indian Safety Professionals Association (ISPA).

Contact the Ministry of Labour and Employment, Government of India for reporting safety violations and seeking assistance.